NEWS

Understanding High Pressure Packages in Electrical Transformers

Release time:

Mar 15,2025

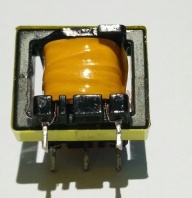

High pressure packages play a pivotal role in the operation and reliability of electrical transformers, especially in high-voltage applications. These packages are designed to withstand elevated pressure levels while ensuring optimal performance and safety. Understanding the intricacies of high pressure packages is crucial for engineers and technicians involved in the manufacturing, installation, and maintenance of transformers.

One of the primary functions of a high pressure package is to provide insulation and protection to the internal components of a transformer. In high-voltage scenarios, the insulation must be robust enough to handle the stresses exerted by electrical fields and temperature variations. High pressure packages typically employ advanced insulation materials that can endure these conditions, thereby extending the lifespan of the transformer and enhancing its efficiency.

Additionally, high pressure packages are essential in minimizing the risk of dielectric breakdown, a catastrophic failure that can occur when the insulating properties of the material are compromised. A well-designed package not only provides superior insulation but also facilitates effective heat dissipation, preventing overheating and maintaining optimal operating temperatures.

In the context of electronic transformers, high pressure packages are equally critical. These transformers often operate in applications that require compact designs while delivering high performance. The ability to manage pressure effectively while maintaining a small footprint is a significant advantage that high pressure packages offer. By optimizing the design of these packages, manufacturers can create electronic transformers that are both efficient and reliable.

Another important aspect of high pressure packages is their contribution to environmental sustainability. By improving the efficiency of transformers, these packages help reduce energy losses and the overall carbon footprint of electrical systems. Ensuring that high pressure packages are designed with eco-friendly materials and processes not only supports regulatory compliance but also aligns with modern demands for sustainability in engineering practices.

For professionals in the electrical and electronic sectors, staying informed about the latest advancements in high pressure package technology is beneficial. Regular training and updates can enhance their skills and knowledge, ensuring they are equipped to tackle the challenges associated with high voltage applications. Collaborating with material scientists and engineers specializing in insulation can lead to innovations that further improve the performance of high pressure packages.

In conclusion, high pressure packages represent a critical component in the realm of electrical transformers, influencing both performance and safety. Understanding their design, functionality, and implications can empower professionals to make informed decisions that enhance the reliability and efficiency of their electrical systems. Whether you are involved in the design, production, or maintenance of transformers, grasping the significance of high pressure packages will undoubtedly contribute to your success in the industry.

One of the primary functions of a high pressure package is to provide insulation and protection to the internal components of a transformer. In high-voltage scenarios, the insulation must be robust enough to handle the stresses exerted by electrical fields and temperature variations. High pressure packages typically employ advanced insulation materials that can endure these conditions, thereby extending the lifespan of the transformer and enhancing its efficiency.

Additionally, high pressure packages are essential in minimizing the risk of dielectric breakdown, a catastrophic failure that can occur when the insulating properties of the material are compromised. A well-designed package not only provides superior insulation but also facilitates effective heat dissipation, preventing overheating and maintaining optimal operating temperatures.

In the context of electronic transformers, high pressure packages are equally critical. These transformers often operate in applications that require compact designs while delivering high performance. The ability to manage pressure effectively while maintaining a small footprint is a significant advantage that high pressure packages offer. By optimizing the design of these packages, manufacturers can create electronic transformers that are both efficient and reliable.

Another important aspect of high pressure packages is their contribution to environmental sustainability. By improving the efficiency of transformers, these packages help reduce energy losses and the overall carbon footprint of electrical systems. Ensuring that high pressure packages are designed with eco-friendly materials and processes not only supports regulatory compliance but also aligns with modern demands for sustainability in engineering practices.

For professionals in the electrical and electronic sectors, staying informed about the latest advancements in high pressure package technology is beneficial. Regular training and updates can enhance their skills and knowledge, ensuring they are equipped to tackle the challenges associated with high voltage applications. Collaborating with material scientists and engineers specializing in insulation can lead to innovations that further improve the performance of high pressure packages.

In conclusion, high pressure packages represent a critical component in the realm of electrical transformers, influencing both performance and safety. Understanding their design, functionality, and implications can empower professionals to make informed decisions that enhance the reliability and efficiency of their electrical systems. Whether you are involved in the design, production, or maintenance of transformers, grasping the significance of high pressure packages will undoubtedly contribute to your success in the industry.