NEWS

Understanding High Pressure Packages in Electrical Transformers: A Comprehensive Guide

Release time:

Mar 20,2025

Understanding High Pressure Packages in Electrical Transformers: A Comprehensive Guide

Table of Contents

1. Introduction to High Pressure Packages in Electrical Transformers

2. What Are High Pressure Packages?

3. The Importance of High Pressure Packages in Electrical Transformers

3.1 Enhancing Electrical Efficiency

3.2 Safety and Reliability Considerations

4. Components of High Pressure Packages

4.1 Insulation Systems

4.2 Cooling Mechanisms

4.3 Pressure Maintenance Systems

5. How High Pressure Packages Function in Electrical Transformers

5.1 The Role of Pressure Management

5.2 Impact on Transformer Performance

6. Maintenance Best Practices for High Pressure Packages

6.1 Regular Inspections and Monitoring

6.2 Common Issues and Troubleshooting

7. Technological Advancements in High Pressure Packages

8. Frequently Asked Questions

9. Conclusion

1. Introduction to High Pressure Packages in Electrical Transformers

High pressure packages play an essential role in the optimal functioning of electrical transformers. As the backbone of electrical distribution systems, transformers must efficiently manage and withstand various pressure levels during operation. This article aims to provide a comprehensive understanding of high pressure packages, detailing their components, functions, and significance in electrical systems.

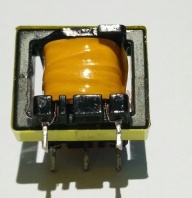

2. What Are High Pressure Packages?

High pressure packages in electrical transformers are specialized systems designed to maintain and regulate the internal pressure of transformers. These packages are crucial for ensuring that transformers operate within safe and efficient parameters. They consist of various components that work together to manage internal pressure, prevent leaks, and maintain insulation integrity.

3. The Importance of High Pressure Packages in Electrical Transformers

Understanding the significance of high pressure packages is vital for anyone involved in the electrical engineering field. Here are some key reasons why they are indispensable:

3.1 Enhancing Electrical Efficiency

High pressure packages contribute to the overall efficiency of electrical transformers. By maintaining optimal pressure levels, these packages ensure that transformers can operate at maximum efficiency, reducing energy losses and improving performance.

3.2 Safety and Reliability Considerations

Safety is paramount in electrical systems. High pressure packages help prevent dangerous situations such as transformer failures, which can lead to significant outages or even catastrophic events. By containing and regulating pressure, these systems enhance the reliability of transformers, thus safeguarding both equipment and personnel.

4. Components of High Pressure Packages

High pressure packages are composed of several critical components that work in unison to maintain desired pressure levels. Understanding these components is essential for effective transformer management.

4.1 Insulation Systems

Insulation is a primary concern in high pressure packages. High-quality insulation materials help prevent electrical leakage and ensure safe operation. These materials must withstand high voltages and extreme conditions without degrading.

4.2 Cooling Mechanisms

Effective cooling is necessary to dissipate heat generated during transformer operation. Cooling mechanisms often involve advanced fluids or gas systems that help maintain temperature stability, thereby preserving the integrity of the transformer and its high pressure package.

4.3 Pressure Maintenance Systems

Pressure maintenance systems are vital for regulating the internal environment of transformers. These systems monitor pressure levels and can adjust them automatically, ensuring that the transformer operates within safe limits.

5. How High Pressure Packages Function in Electrical Transformers

High pressure packages operate through a series of interactions among their components to maintain optimal pressure levels.

5.1 The Role of Pressure Management

Pressure management is crucial for transformer performance. High pressure packages continuously monitor and adjust the internal pressure, ensuring it remains within specified limits. This proactive management helps prevent overheating and electrical failures.

5.2 Impact on Transformer Performance

The functionality of high pressure packages directly impacts the overall performance of transformers. Efficient pressure regulation leads to enhanced performance, reduced energy losses, and prolonged equipment lifespan. Regular maintenance of these packages is essential for sustaining their effectiveness.

6. Maintenance Best Practices for High Pressure Packages

Maintaining high pressure packages requires careful attention to detail. Implementing best practices can greatly enhance their reliability and performance.

6.1 Regular Inspections and Monitoring

Routine inspections are vital for identifying potential issues before they become serious problems. Monitoring pressure levels, insulation condition, and cooling efficiency helps maintain optimal operation.

6.2 Common Issues and Troubleshooting

Common issues with high pressure packages include pressure fluctuations, insulation degradation, and cooling system failures. Understanding these problems and having a troubleshooting plan can mitigate risks and enhance safety.

7. Technological Advancements in High Pressure Packages

The field of electrical engineering is continually evolving, and so are high pressure packages. Recent advancements in materials science and engineering have led to improved designs that enhance performance and reliability.

Modern high pressure packages often incorporate smart technologies that use sensors and data analytics to optimize performance. These innovations allow for real-time monitoring and predictive maintenance, significantly reducing the risk of failure.

8. Frequently Asked Questions

What is the primary function of high pressure packages in transformers?

High pressure packages maintain and regulate pressure within electrical transformers, ensuring safe and efficient operation.

How can I identify issues with my transformer’s high pressure package?

Regular inspections and monitoring pressure levels can help identify potential issues. Look for fluctuations, unusual noises, or signs of wear.

What maintenance practices should be followed for high pressure packages?

Routine inspections, monitoring, and addressing common issues are key maintenance practices for high pressure packages.

What are the risks of not maintaining high pressure packages?

Neglecting maintenance can lead to transformer failures, safety hazards, and increased operational costs due to inefficiencies.

How have technological advancements improved high pressure packages?

Recent technologies include smart sensors and data analytics that enhance monitoring, predictive maintenance, and overall performance.

9. Conclusion

Understanding high pressure packages in electrical transformers is essential for anyone involved in the electrical engineering field. These systems are integral to maintaining safe, efficient, and reliable transformer operation. By being informed about their components, functions, and best maintenance practices, we can enhance the longevity and performance of transformers. Embracing technological advancements will only pave the way for a more efficient future in electrical distribution systems.